Model No.︰DT70

Brand Name︰DT

Country of Origin︰China

Unit Price︰US $ 120000 / set

Minimum Order︰1 set

High Quality Fish Feed Pet Food Making Machine

Specifications:

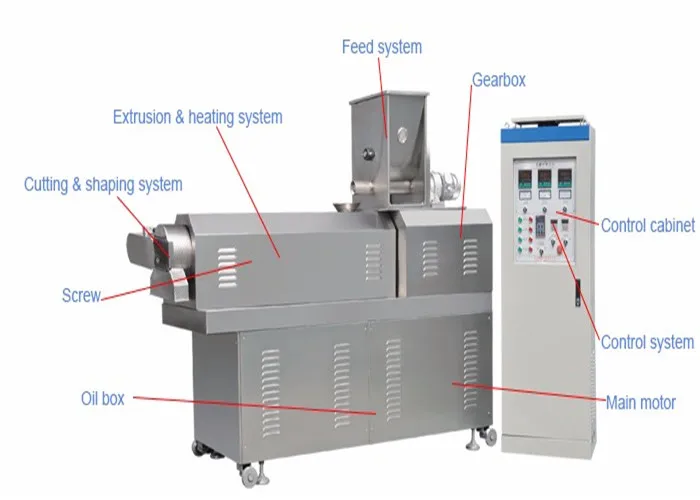

Fish Feed Extruder

1. Food Grade Stainless Steel

2. LG, FUJI Electric Parts

3. 1 Year Warranty

4. CE, ISO9001

Description :

.Pet Food machine are the all-automatic and food grade processing line. You can make any shape of the pet food according to different market requirements.

Hot Sale High Quality Automatic Double Screw Dog Fish Feed Extruder uses meat meal, fish meal, corn powder, soya meal and other grains powder as main materials to make the pet food, such as dog, cat, fish, bird food etc. With different shapes and tastes by changing the dies and formulations. It adopted Modular Circular Groove Screws and by changing the screw assembling sequence,slenderness ratios different products can be made such as corn flakes, puffing snacks, protein etc.

Details:

1. Raw Materials: Meat meal, Fish meal, Corn powder, Soya meal and other grain's powder

2. Products: The pellet food, like dog, cat, fish, bird food etc.

3. Capacity: 100-1200KG/H

4. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage of different countries.

5. Machines Materials: All the machines are made by food grade stainless steel.

Introduction:

Flow chart:flour mixer→screw conveyor→conditioner→double screw extruder →air conveyor→dryer→double drum flavoring line

1.Flour mixer:

Mix all raw material, rice flour, wheat flour, corn flour, bean flour and other types of flour.

Capacity: 3kw 100-150kg

4kw 150-300kg/h

7.5kw 300-500kg/h

2, screw conveyor

Transport the raw material from mixer into the extruder.

3, Double screw extruder

Technical parameter:

| Model | DT95 | DT90 | DT85 | DT70-1 | DT70 | DT65 |

| Installed Power | 100.7kw | 82.5kw | 92kw | 61.5kw | 46.5kw | 35kw |

| Main Motor Power | 90kw | 75kw | 75kw | 45kw | 30kw | 22kw |

| Capacity | 1500-2000kg/h | 800-1200kg/h | 400-500kg/h | 200-260kg/h | 200-260kg/h | 100-150kg/h |

| Dimension | 4.9×1.2×

2.7m |

4.7×1.2×2.5m | 3.9×1.2×1.8m | 2.8×1.0×1.9m | 2.8×1.0×1.9m | 2.7×0.9×1.8m |

Application:

Snacks, pet food, breakfast cereal, corn flakes, all types of puff food.

4.drying machine:

It is used to dry all kinds of materials.

Technical parameter:

| Model | Electric(gas/diesel) Consumption | Heating Temperature | Output

|

Dimension

|

| Three-layer electric dryer | 27kw/h | 200°C | 150kg/h | 5400*1300*2000mm |

| Five-layer electric dryer | 45kw/h | 200°C | 300kg/h | 5800*1300*2400mm |

| Three-layer gas/diesel dryer | 7-10L/h | 200°C | 150kg/h | 6500*1600*2000mm

|

| Five-layer steam dryer | 28.4kw/h | 200°C | 800kg/h | 9600*1700*3500mm |

| Seven-layer dryer | 48kw/h | 90°C | 100kg/h | 9000*2400*3000mm |

5.Double roller drum capacity: 200-500kg/h It is used to mix all kinds of flavors to make our food taste better

It is used to mix all kinds of flavors to make our food taste better

Food Samples:

Specifications :

1. Stable performance: adopting frequency speed controlling with high automation and stableperformance.

2. Barrel: the barrel is euro-style rectangle barrel. The reflex refrigeration channel is optimized and disposed, which can make temperature difference in different smaller areas.

3. The material of the screw can be 38CrMoALA, under initiation treatment, or make of alloy bushing which is anti-wear.

4. The forced lubricating system can also extend the usage time of the extruder.

5. The Auto-temperature control system makes the temperature controlling much more direct and the parameters more precise.

7. Self-cleaning: the screw has the capability of self-cleaning. No need to disassemble when stooping.

Competitive Advantages:

1. Guaranty: One Year.

2. One set of consumable accessories will be provided with the machine.

3. Any question, you can mail/call us at any time. And our most experienced engineers are assigned to give consulting service, and always available for dispatching abroad.

4. All spare parts are always available for delivery.

5. Manual is in English.

6. Minimum order: 1 set

7. Prompt Delivery: 15-20 working days after receiving deposit

8. Installation: sending one technician to the customer's factory for installation and training.

9. Packaging: firstly packing with plastic inner side, then strengthening with wooden case outside.

Payment Terms︰ TT