Model No.︰DLG76

Brand Name︰DLG76

Country of Origin︰China

Unit Price︰US $ 24000 / set

Minimum Order︰1 set

Product Description Introduction to cheetos processing line:

Jinan Datong Chetoos production line is the use of maize (corn maize) as raw material, after the host squeeze into irregular puffed food, the taste can be made into different taste crisp products, loved by consumers. The extruder with vibration feeding hopper, and adjustable size of raw materials flow. Feed screw rotation speed controlled by frequency conversion, can be adjusted. Mechanical gear linkage, realize manual control extrusion head clearance, the handwheel control stand linkage, may make it easier for feed screw into the extruder barrel.

Characteristics of Swival Chetoos production line :

1,Latest rubbing type extrusion type technology make the product crispy and delicious

2,Delicate precise control system

3,Brass casting main components with good friction resistance

4,Vibrating feeding makes material more even

Cheeots Snacks/Corn Curls /Kurkure/Nik Nak Snacks Process Line adopts American Extrusion technology, it takes corn grits(not powder) as raw materials , through single screw rotary head extruder direclty expanding out twist corn curls. After this it will be processed with dryer or fryer to get final crispy cheetos snacks.

The processing line is foodstuff equipment researched and developed on the basis of international advanced technology. The performance and quality have reached the highest international level of the same line. From feeding materials, extruding and inflating, roasting, spraying to finished products are done once time with automation. We fill the gap of the first-class food produced with extruded and inflated technology.

Function

This processing line can be used to produce different sizes of kurkure snacks, the size and thickness can be adjusted .

1) Capacity: 150kg/h

2) Raw material: Corn Grits.

Main Feature

1) Stable performance: adopting imported frequency or electromagnetic controlling

system, high automation and smooth operation

2) Permanent working life: with special material and technology, the screw and nut

involved can work continuously for 1 year under conditions of high wear and pressure

Processing Flow Chart

Flour Mixing - Extruding and inflating - Conveyor - Frying – Sifting - Flavoring -Cooling

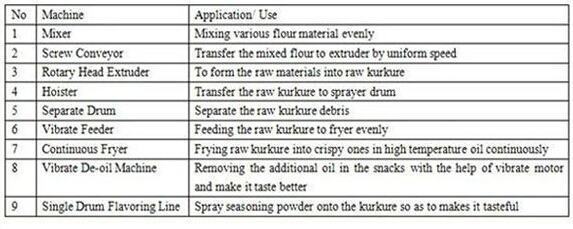

Equipments List

Mixer—— Screw conveyor—— Rotary Extruder—— Hoister——Continuous Fryer ——Sifter -- Hoister ——Favor Roller - - Cooling Conveyor

Packaging & Shipping

Packing: Simple packing stretch film (Based on the customers' need adopt the wooden case or wooden pellets, etc.)

Transportation: According to the contract, our company could in charge for the shipment or you prepaid. We will choose the most timely and safe way transportation.

Our Services Pre-sale services:

1> Provide the free consultation of the equipment

2> Provide the standard device and the flow chart

3> According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

4> Welcome to visit our factory or the domestic clients’ factory.

Services during the sales:

1> Help client design the factory and offering professional advice, free engineering drawing for the

factory layout.

2> Inspect the machine before leaving the factory.

3> Oversea install and debug the equipment.

4> Train the first-line operator.

5> Provide the basic formula

After sale services:

1> 24 hours online service

2> Engineers available to service machinery overseas

3> Provide technical exchanging

Payment Terms︰ TT