Model No.︰DT

Brand Name︰DT

Country of Origin︰China

Unit Price︰US $ 120000 / set

Minimum Order︰1 set

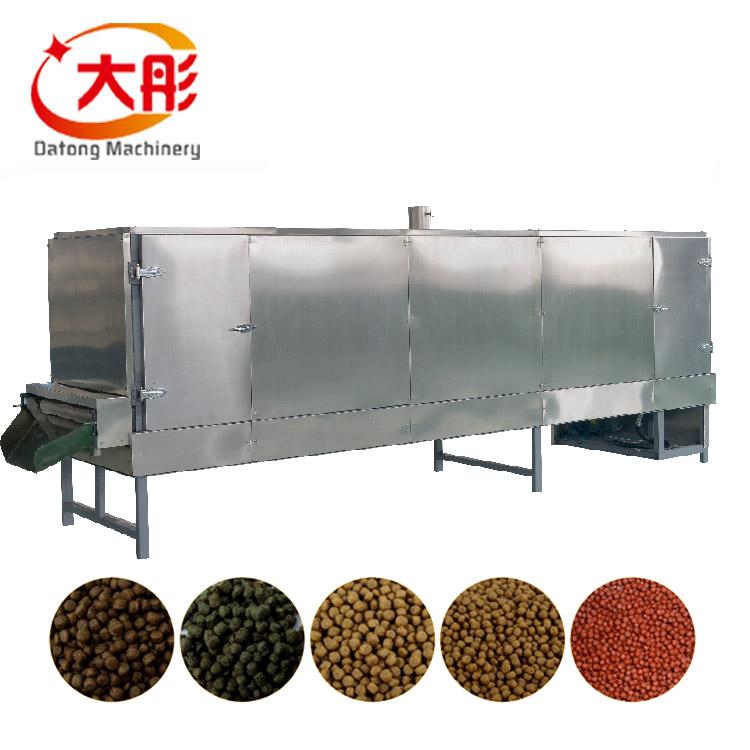

Floating Fish Feed Making Machine at Best Price in china

Product Description

We are instrumental in offering Floating Fish Feed Making Machine to our clients. Fish feed processing / pet food line, use meat power, fish meal, bone meal, corn floir, cereals, and beans are used as raw materials. to produce floating / sinking fish feed with tinique taste and new shape, such as heat, bones, stars, traingle, circles, etc. Meat all kinds of pet, such asL fish, dog, cat, shrimp, trutles, etc. Let the pet eat jappier and live healthier. and this line can also make the cored filling pet food, it will be more popular with modern pets.

1. Raw materials of Floating Fish Feed Making Machine :

adopts corn flour, fish meal, bone meal, meat meal, soyabean powder etc as raw materialsSmall

2. Flow chart of Floating Fish Feed Making Machine:

Mixing system---Extrusion system----Drying system----Flavoring system--Packing system

2. Products of Floating Fish Feed Making Machine:

different shapes are made by adjusting the dies from extruder

1.0mm,2.0mm,2.5mm,3.0mm,3.5mm,4.0mm,4.5mm...10.0mm depend on fish food dies size.

You can use this fish food making machine to produce different size pellet by change the extruder dies easily.

3.Floating Fish Feed Making Machine Advantage :

1. The screw is made of alloy (38CrMoAL) by nitriding process, high strength and wear-resting. And it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

2. It adopts speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine guarantees stable materials feeding in the whole food process.

3. The gearbox has automatic lubrication function, with extends gear life.

4.DT70-W Floating Fish Feed Making Machine Parameter:

|

Name |

Floating Fish Feed Making Machine |

|

Material |

Stainless steel and carbon steel |

|

Whole line Size: |

about 25.0*4.0*4.0m (Free worksho design drawing)

|

|

weight: |

6000-7000kg |

|

working Power |

380v 50HZ three phase (Customized) |

|

Packing way |

woodcase or plastic film |

|

Payment |

T/T or L/C at sight |

|

Shipment date |

in about 25-35 days |

5.SLG85 fish food machine installing in africa customer factory:

Our company engineer go to customer factory to help them and training workers on the spot.h

Company Information

JINAN DATONG EXTRUSION MACHINERY Co., Ltd is an industry and trade integrated enterprise. The company is committed to R & D extrusion machinery and related ancillary equipments. It is covering mainly machinery and equipment for corn meal milling system, corn flakes/breakfast cereal system, baby food system, corn puff snacks system, pellets system, artificial rice system,soy nuggets system; as well as pet food/fish food system.

Our Services

1)Free management of equipments' long distance shipping;

2)Provide factory layout according to your factory size in advance;

3)Provide the basic formula;

4)Inspect the machine before leaving the factory;

5)Oversea installation and commissioning the equipment;

6)Technician will work with your workers together and teach your workers how to install machines, how to operate machines, how to maintain machines during daily working;

7)Our engineers will teach your workers how to clean the extruder, how to change the screw, how to change barrel etc, and provide technology support with you forever;

8)Provide English Version of Installation/Operation/Service/Maintenance Manual.

Packaging & Shipping

1. Inside package is plastic film, outside is wooden or plywood case, or fumigation package with certificate, (based on the customers' need).

2. Ship, train, express or upon clients' demands.

FAQ

1:How big is the power of you machine?

A:We design the power of the machine based on the characteristics of the material you plan to process

2:How is the quality of you prodects?

A:Our products are certificated with CE quallity inspection

3:What's the difference between microwave dryeer and normal dryer?

A:Microwave process is more efficiency and evenly

4:What's you after sale service?

A:We will dispath our engineer to your factory to guide you installation,commissioning and worker taining

5.How is the payment?

Answer: 40% TT as downpayment, 60% TT or L/C before shippment. Before shippment,welcome to inspect the machine

Contact Us

Kevin Lee

Jinan Datong Machinery CO.,LTD

Website: www.dofoodmachine.com

MP/whatsapp: 0086-15264102980

Wechat:794950680

Price Terms︰ USD

Payment Terms︰ TT

Packing︰ woodcase

Lead Time︰ 30days