Automatic Extruded Corn Snack Food Processing Line Puffed Corn Snack Machinery Puffed corn snacks food machine

Product Description

This Core Filling Snack Food Extruder Making Machine is improved and developed based on advanced technology by Jinan Datong Machinery Co., Ltd. This puffed corn snack making machine has features of flexible collocation, extensive applied raw materials, various snack and easy operation. It is full automatic from mixing, extruding, shaping, cutting, drying to flavoring in one-pass operation.

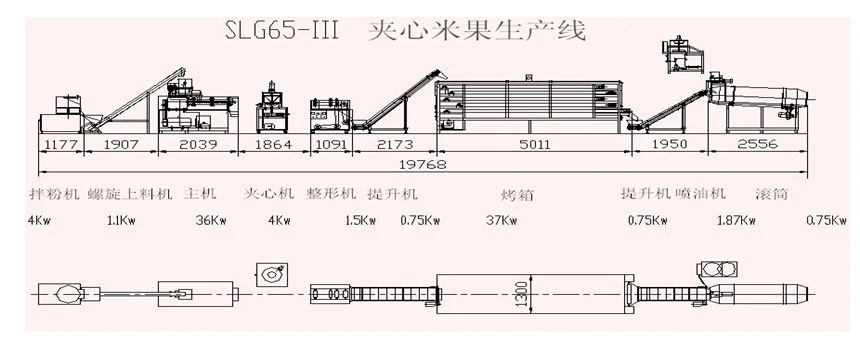

Puffed Food Processing Machine Flow chart:

Mixer-Screw conveyor-Twin screw extruder-Air conveyor-Dryer-Flavor machine(Roller)-Cooling machine Taking SLG- 65 as example, it is the standard configuration.

1. Raw materials: Rice flour, corn flour and so on.

2. Products: By changing the moulds and process technology, this line can produce core-filled snacks, such as chocolate filled bar, cream filled pillow, rice cake, cereal bar, sheet snacks, etc.

1. Mixer : Mix the raw material equally

2. Spiral Elevator : Elevate the raw material into the extruder

3. Extruder : Cook the raw material with high temp and pressure to make them puffed

4. Injector : inject chocolate / jam/ butter to the center of the snacks

5. Shaping Machine: Cut the core-filled snacks into certain length

6. Air Blower : Take the snacks to the oven

7. Oven : Bake the snacks to be crispy

8. Flavoring line : Spray oil and powder type seasonings to make different flavors

Product sample:

Puff Corn Snacks Food Extrusion Processing Line Extruder Technology:

|

Model

|

Installed Power

|

Consumption Power

|

Dimension

|

Capacity

|

Application

|

|

SLG65

|

50KW

|

38KW

|

25500×3000×3000mm

|

100~150kg/h |

Core filling snack

Puffed snack

|

|

SLG70

|

83KW

|

62KW

|

27400×3200×3100mm

|

200~300kg/h

|

Core filling snack

Puffed snack

|

|

SLG85

|

122KW

|

91KW

|

27900×3000×3500mm

|

350~500kg/h

|

Core filling snack

Puffed snack

|

Company Information

Jinan Datong Machinery Co.,Ltd. is a professional supplier of food processing machines. Our company's Motto is: "Technology Makes Easy". We offer to cooperate with our customers for mutual and beneficial development. All Inquiries are welcome.

We are located in Jinan, the Capital of Shandong Province. Jinan Datong Machinery Co.,Ltd. is vested with many staffs with many years of experience in supplying the food processing machines.

Our main products line include snake food extrusion machine, fish feed processing line, pet food processing line, soya meal/meat processing machines, industrial micro wave oven, packaging machines, rice cake machine etc... Most importantly, we also provide formulas, technology supports, machine inspection service, etc.

Welcome to our company and discuss the business with us.

Our Services

Before sale services:

1.Provide the free consultation of the equipment.

2.Provide the standard device and the flow chart.

3. According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

Services during the sales:

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2.Welcome to visit our factory or the domestic clients’factory.

3.Inspect the machine before leaving the factory.

After sale services:

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. We will provide 1-2 engineer to the client's factory for the installation and training. The client need provide room, food, round-trip transportation, visa fee and a nominal daily subsidy per person.

Packaging & Shipping

Packing:Inside: plastic bag. Outside: wooden case (adopt the wooden case or wooden pellets depended on clients' requirement).

Shipping:Train, express, or upon clients’ demands.

FAQ

Q: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 20-25 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 40% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact Us:

Any inquiry or question, feel free to contact me! I will reply you as soon as I can!

Automatic Corn Snack Food Processing Line Puffed Corn Snack Machinery

Puffed Food Processing MachinePuffed Food Processing MachinePuffed Food Processing MachinePuffed Food Processing MachinePuffed Food Processing Machine Puffed Food Processing MachinePuffed Food Processing MachinePuffed Food Processing Machine