High quality Industrial Artificial Rice Production Line Artificial Rice Extruder MachineNutrition Rice Puffing Making Machine

Product Description

Automatic artificial puff golden nutrition rice processing linehasadvantageofhighdegreeautomationandenergysavingItcanuserice,millet,brownrice,buckwheatandothercerealsasrawmaterials.Afterstrengthenmixedwithavarietyofvitamins,proteinsandminerals,andextruded,mixedandcuredinextruder,itbecametoriceagain.Theusageissametonaturalrice,butmoresampleandconvenientthanbefore.Itnotonlynutritionbutalsoadaptstothefastrhythmofthemodernlife.

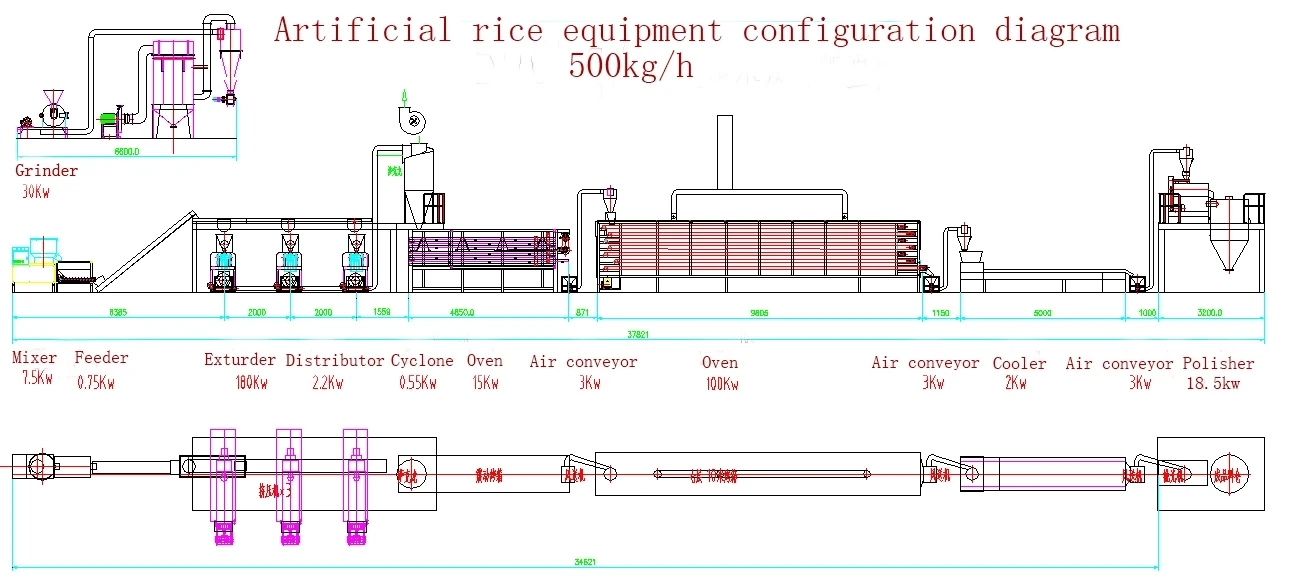

artificial rice processing line:

Mixer--Screw conveyor--Twin screw extruder--Vibrating screen--Air conveyor--Dryer--Cooling machine.

2. Artifical riceproductionprocessing line:

3.The equipment parameter of artificial rice processing line:

| Model |

Installed power |

Actual consumption |

Main power |

Output |

Dimension |

|

DT65

|

34KW |

28KW |

22KW |

100-150kg/h |

2400*1200*1800mm |

| DT70 |

42KW |

30kw |

30kw |

160-200kg/h |

2600*1200*1800mm |

| DT75 |

85kw |

60kw |

55kw |

200-300kg/h |

2600*1200*1900mm |

| DT85 |

92kw |

75kw |

75kw |

300-400kg/h |

4500*1600*2000mm

|

| DT90 |

135kw |

91kw |

75kw |

400-600kg/h |

4500*2000*2000mm |

4.Detail of artificial rice processing line:

|

Name: high speed mixer

Dimension(m): 1.1×0.8×1.4

Motor Power: 4KW

Speed: 400rpm

Throughput: 30kg per loading (5-6 minutes per loading)

Functions:

mix raw powder material with water Features:

1. stainless steel material(1.5mm).

2. new handle-opened design of discharge holes,no materiel

3.High speed can mix material better than other slow mixer.

|

|

Name: screw conveyor

Dimension(m): 3.2×0.6×0.7

Motor Power: 1.1KW

Screw speed: 300rpm

convey height range: 1.5~2.5M

barrel diameter: Φ160mm

Function:

Power material can be conveyed in the stainless steel roller to the feeder of extruder without leaking, dust and pollution

|

|

|

Name: Artificial Rice Production Line Artificial Rice Extruder Machine

Dimension(m): 2.6×1.0×1.3

Main Motor Power:45KW Feeder motor:0.75kw

Cutting motor: 1.5kw Heating power:10kw

Extruder diameter:Φ70 mm

Function:

Extrude and cook raw material into different size and shapes

Features:

Screw material is 38CrMoAl with nitriding treatment, the hardness is

60HRC.. The barrel also use good material, hardness is 55HRC.

The gear box has forced lubrication system.

All motors can be adjusted the speed by Inverter.

The Extruder can change different molds to produce different shapesproduct.

|

|

Name: multi-layer dryer

Dimension(m): 8.4×1.3×1.8

Heating Power:60kw

Motor power:0.75kw

Belt speed:0.1-10M/minute

Temperature: 20-200℃

Features:

The net belt running speed can be controlled by Inverter, to change the food drying time in the dryer.

Heating adopts the electric heating.

It has automatic temperature Control system.

The belt and the cover are all stainless steel.

|

|

Packaging & Shipping

1).Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finally pack them with wooden case.

2)Customer's requirement is available.

3).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country); by ship-please tell me your delivery port.

Company Information

Our Services

1)Consultation service before, during,and after sales.

2)Technician will work with your workers together and teach your workers how to install machines,how to operate machines, how to maintain machines during daily working.

3)Our engineers will teach your workers how to clean the extruder, how to change the screw,how to change barrel etc, and provide technology support with you forever.

4)Provide the basic formula.

5)Inspect the machine before leaving the factory.

FAQ

1.What's the pre-sale service of your company?

Related machines’s technical parameter will be supplied to customer.

1. According to customer’s factory size, factory layout can be provided inadvance.

2. According to customer’s material cost, general formulation can beprepared well.

3. Special machine can be supplied as customer’s request.

4. Professional Advice about Market, machines, processing , materials,packing can be supplied.

5. Suggesting professional ship agent or helping book ship as customerrequest.

2. What's the after-sale service of your company?

1. Allocationchartasthebuyer’srequestwillbesupplied.

2. Operationmanualwillbesuppliedaftershipment.

3. Oneyearwarrantee,lifetimemaintenancewithcostprice.

4.Freeeasybrokensparepartswillbesentwithcontainer.

5. Firstinstallationcanbedonebyengineer.

6. Trainingworkersincustomer’sfactory.

3. If machines wearing parts need changing, what should we do?

We can offer the wearing parts all the time, and offer video.

4. What's the payment terms if we want to buy the machines?

L/C, T/T 30% down payment, 70% balance before delivery.

5. What is the minimum order?

Yes, our company mainly deals with wholesale deals,but if you insist buying one set,or you just need one set,we would be very likely to make the MOQ as 1 set for you though.

6.How long is the warranty time for your products?

Our officially promised warranty time is one whole year after delivery at best.

7.I haven't done business with you guys before,how can i trust your company?

we've been golden suppliers for years.what's more,we've got quite a lot authority certificates,for example,CE, Alibaba on site check certificate. If you also have some questions, welcome to visit our factory, we will provide the best service and machines for you. I hope those above will be persuasive enough.

8. Do you give any discount ?

I'll surely try my best to help you get those by the best price and good service at the same time.