Dry dog food making machine supplier online

Product Description

1. Main feature:

It can make kinds of feed, such as food fish, catfish, shrimps, crab, etc. The fish pellet made by the machine can float on water more than 24 hours. Gelatinization degree can reach 90%, enhance the output of fodders, it is suitable for making floating feed, pet food, fish fodder. The diameter of particle is 0.6-16mm. Promising fodder output evenly and continuously.

2. Raw materials: Adopts soya meal, fish meal, bone meal, rice bran etc. As raw materials.

3. Dog food making machine Flow of chart:

Mixer -Screw conveyor -Twin-screw extruder -Eelevator-Dryer-Hoister -Flavoring line -cooling conveyor.

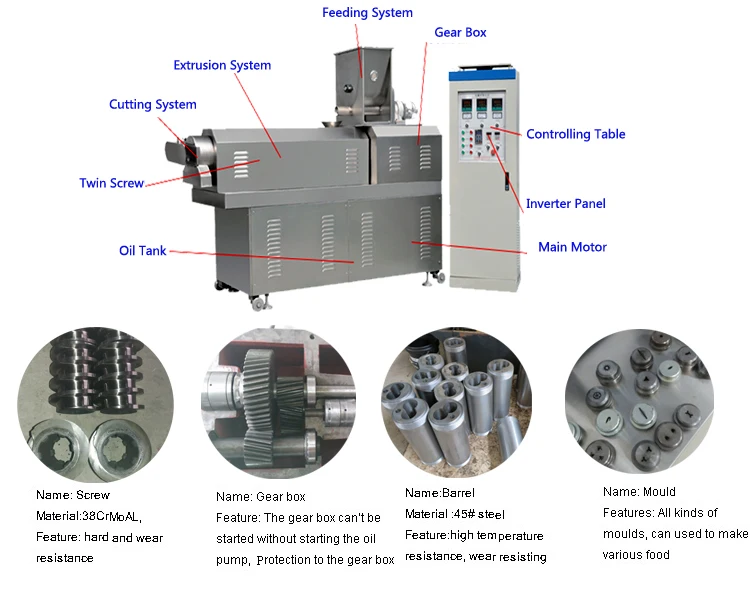

4. Component details:

4. Component details:

Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries.

Machine materials: All the aquaculture fish feed machine production line are made by stainless steel, this line is with reasonable design and with high automation; The screws are made by alloy steel, with building block system structure and self-cleaning function.

5.Main Parts of Dog food making machine:

A. The screws are made by alloy steel (38CrMoAl) and special craft by nitriding process, The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

B. The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating.

C. The gearbox has automatic lubrication function, with extends gear life.

D. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

E. Siemens(China) brands electronic parts used in the controller box, make sure the extrusion process perfect.

F. Main Motor from Siemens(China), ensure its powerful extrusion and excellent performance.

6. Dog food making machine Parameter:

|

Name

|

Dry dog food making machine

|

|

Material

|

Stainless steel and carbon steel

|

|

Whole line Size:

|

about 20.0*4.0*4.0m (Free worksho design drawing)

|

|

weight:

|

5000-6500kg

|

|

working Power

|

380v 50HZ three phase (Customized)

|

|

Packing way

|

woodcase or plastic film for Best Price Floating fish feed making feed pellet machine price fish feed machine

|

|

Payment

|

T/T or L/C at sight

|

|

Shipment date

|

in about 25-35 days

|

|

Advantage

|

1).Our processing line adopt international advanced technology, the pellets size are very even.

2).we can adjust the cutter speed and the dies to get the different diameter and the length product

3).The Electric heating device system can control the temperature accurately

4).High temperature and high pressure can kill the salmonellosis andbacterial infections.

5).This line can produce high-protein fish feed.

6).The processing line can produce both floating and sinking fish feed.

7).This line only need three workers

|

oating sinking fish feed pellet machine extruder floating fish feed pellet machine farming equipment

Company Information

Jinan Datong Machinery Co., Ltd is a professional food machinery manufacturer in Jinan city shandong province China.Our company congregates an exceptional food machine engineering team, personal customer service center and highquality manufacturing capabilities have evolved exponentially,We are working hard on explore constantly not only in the research of extrusion technology, but also in food technics to benefit our clients producing newfangled food in their markets. It making us become one of the preeminent providers of reliable extrusion equipment world-wide.

Our Services

1)Free management of equipments' long distance shipping;

2)Provide factory layout according to your factory size in advance;

3)Provide the basic formula;

4)Inspect the machine before leaving the factory;

5)Oversea installation and commissioning the equipment;

6)Technician will work with your workers together and teach your workers how to install machines, how to operate machines, how to maintain machines during daily working;

7)Our engineers will teach your workers how to clean the extruder, how to change the screw, how to change barrel etc, and provide technology support with you forever;

8)Provide English Version of Installation/Operation/Service/Maintenance Manual.

Packaging & Shipping

Packing: inside plastic bag, outside wooden case for core filling snack food puffed food making machine (Based on the customers' need adopt the wooden case or wooden pellets, etc.).

Transportation: shipping, train, express or upon clients' demands.

1. Inside package is plastic film, outside is wooden or plywood case, or fumigation package with certificate, (based on the customers' need).

2. Ship, train, express or upon clients' demands.

FAQ

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about theDog food making machine?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer’s factory for 7-14 days period installation and training to the operators.Best Price Floating fish feed making feed pellet machine price fish feed machine

A: yes, we supply formulas to buyer.

Contact Us

Kevin Lee

Jinan Datong Machinery CO.,LTD

MP/whatsapp: 0086-18660429170